Our Mission Statement is simple:

“To be the premier remanufacturer of Transmissions, Axles and Hydraulics.”

TRC is a wholesale only program. We want to be your partner, not your competitor.

TRC separates ourselves from local providers with our deep Original Equipment (OE) connections and access to critical product, process and diagnostic information. TRC separates ourselves from other national providers with our investment in nationwide distribution, management and quick, decision making.

We strive to perfect this balance to bring our customers the

best of both worlds:

• World class capabilities • Nationwide

access to expertise, service and product

Multiple OE Affiliations:

• TRC is recognized as one of the top two remanufacturers of

commercial vehicle drive train components in North America

allowing us to provide the best cost and quality combination for

your company’s needs.

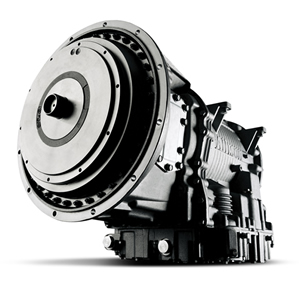

• TRC only supplies Allison transmissions remanufactured in our dedicated facilities with 100% Allison genuine components.

• TRC is one of a select few remanufacturers

authorized by Eaton to remanufacture manual transmissions,

utilizing their nationwide warranty network to support our

authorized product.

• TRC has been chosen by Meritor to be an Authorized rebuilder for drive axle carriers.

• We are a Dana Authorized Spicer Off-Highway Service Center and are prominent warranty center for Muncie, Eaton Hydraulics, Fabco and many more.

• These direct relationships ensure we have access to the latest

design changes and these

improvements are built

into our remanufactured units to ensure the highest quality of

product performance.

• TRC has direct relationships with

virtually every major supplier to the commercial truck market.

Quality Orientation:

• TRC is a

specialist, not a generalist. This focus on the commercial

vehicle drive train affords us the opportunity to provide the

detailed expertise, product and services required as products

evolve and become more complex. By not trying to be all things

to all people, TRC is your best bet for the mundane as well as

the complicated needs related to the drive train.

• By

centralizing the remanufacturing process into seven product

centric facilities, we can control quality through a

standardized, industrialized and repeatable remanufacturing

process. This means that each component is fully disassembled

and consistently remanufactured to an OE specification.

• TRC

has a best in class testing regiment with 13 electronic

dynamometers across the enterprise.

• We use Kaizen and Lean

manufacturing techniques extensively across the company to drive

quality

into every process. We conduct a minimum of four

week-long Kaizen exercises annually and employ two full time

lean experts.

• An industry leading, nationwide warranty

experience is a reflection of the systematic approach

we

employ for quality. Feedback to the customer as well as the shop

floor is immediate and fact based to drive improvement in our

process and your business.

based to drive improvement in our

process and your business.

Nationwide Expertise:

• TRC has

multiple Regional Sales Managers working in the field to serve

your specific needs.

• We have 28 strategically located

distribution centers across the nation to quickly meet your

unique drive train requirements.

• TRC utilizes 100 delivery

trucks to respond immediately to your product needs and provide

free pick up and delivery of orders.

• TRC has a 95%

fill rate on complete unit orders within 24 hours.

Sustainability:

Remanufacturing was "green" before green was cool. As a matter of fact, worldwide, the energy saved during remanufacturing is equivalent to the energy produced by 8 nuclear power plants. While remanufacturing has begun in numerous industries, the heart of the business remains in the remanufacturing of vehicle components. TRC has been at the forefront of the remanufacturing industry for 30+ years, salvaging over 160,000 tons of steel destined for landfills.

Recent studies have confirmed that a remanufactured transmission or differential consumes 85% less energy than a brand new component – with no drop off in performance.

TRC is a long time member of APRA and a charter member of MERA, the leading associations focused on the automotive remanufacturing industry.

Rethink Reman

Download MERA's Infographic“First of all, let’s clarify the

difference between a remanufactured transmission and one that is

simply rebuilt. TRC transmissions are totally remanufactured,

returning them to the latest blueprint specifications and tested

to original equipment standards,” explains Morrow. “The typical

rebuilt transmission is only repaired to the level of failure.

That means any components beyond this level are left intact.

Additionally, testing procedures often vary among individual

rebuilders. Having been exposed to TRC’s process, I can attest

that they have a robust remanufacturing and testing process—they

are not just a rebuilder.”

Jim Morrow

Former President

Detroit Diesel Remanufacturing Corp.